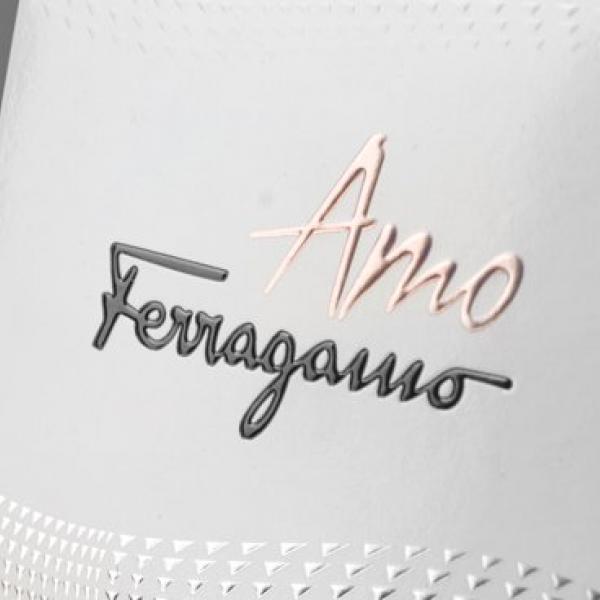

Packaging that oozes elegance and sophistication

When packaging is in harmony with brand communications

Salvatore Ferragamo has selected the mastery of Bolognese packaging company Industrialbox and the high quality of Sappi's Algro Design to create the packaging for its new women's fragrance, Amo.

Flawless white, trails of embossed details in stunning silver: the new packaging for Salvatore Ferragamo's fragrance, Amo, exudes style and elegance. The attractive glacial motif on the box is complemented perfectly with a rainbow holographic finish and with its interior in a surprising pale pink – the same pale pink as the bottle's contents. The box's design is rounded off by a cascade of small prisms, which reflect the light. The fragrance is simply the perfect choice for strong, independent and elegant women who seize every opportunity life offers them. It is for these women that we have created this fragrance.

This refined packaging is the result of a successful collaboration between the great Italian fashion brand Salvatore Ferragamo and the Bolognese packaging designers Industrialbox. An understated yet effective design, this elegant paperboard product in fact encompasses all the expertise of Ferragamo's creative team, as well as all Industrialbox's experience in producing high-end packaging. Renowned partners were involved in bringing the design to life, including Sappi, who produced the Algro Design paperboard used for the design and Plastic Stratosfera, who were in charge of laminating the holographic film.

Product research

Ferragamo is a loyal client of Industrialbox, who have been responsible for creating packaging solutions for various fragrances, including Signorina and Emozione, and the exclusive Tuscan Soul line. For the latest fragrance, the Bolognese company's team has been involved in the process since the new perfume was presented to a select group of customers, partners and collaborators at Palazzo Vecchio in Florence, Italy.

Starting with ideas and creative suggestions from the client, who came up with the packaging's design, Industrialbox researched the best way to achieve these ideas. This involved beginning with the primary packaging – that is, the glass bottle – and considering the box's structural design. Shipping tests were conducted to check its sturdiness. "A box or packaging solution of this kind is never just a box or packaging solution. It must be able to protect its contents – in this case a luxury item that is destined to suffer numerous external stresses, for example, from exposure to extreme temperatures. The packaging's purpose is to enclose and showcase the product, convey key branding messages and keep the contents intact", says Carlo Gregori, president of Industrialbox. The file with the structural design was then sent to the client who applied the chosen graphics to the packaging and sent it back to Industrialbox.

Prototyping

The next stage comprised of technical testing, with the initial goal of finding the right combination of materials, printing and finishing technology. One of the primary issues was the choice of paperboard: not only did it need to have a perfect white tone, but it also needed to boast an excellent level of elasticity, necessary to realise the pointed prism details. At the same time, the paperboard needed to offer constant mechanical resistance, so as to allow a range of successive processes, while maintaining the print and finishing register. After several tests and mock-ups, the combination of a particular brass cliché, selected for embossing the prism's, combined with Sappi's 330 g/m² Algro Design Paperboard, offered the best solution.

"The Algro Design paperboard by Sappi was the only feasible option we had to realise this design, from both an aesthetic and a technical point of view", explains Carlo Gregori. "It was our client Ferragamo's biggest wish to achieve a design that not only showcases a flawless white finish, but also fully meets all the technical requirements imposed by processing: elasticity for the embossed elements and optimal mechanical resistance, which allows us to realise all the decorative details perfectly in register".

Production

The packaging proposal finally approved by the Ferragamo team, who led the project, involved several steps: first, the paperboard was printed with UV offset technology before undergoing a process of cold lamination. Plastic Stratosfera carried out this lamination process with a special holographic film produced in the US. The card was printed again to ensure the perfect opacity of the black font. Next, the prisms in relief were created in register, through debossing. At this stage, the card was die-cut, folded and glued.

About Algro Design by Sappi

Algro Design by Sappi is one of the most popular SBB paperboard variants. It is known for its bright and uniform white colour, its high resistance to light and its soft and silky surface. It is available in three versions:

- Algro Design, with double coating on the front and without coating on the back, available in weights between 160 and 400 g/m²

- Algro Design Card, with double coating on the front and single coating on the back, available in weights between 235 and 345 g/m²

- Algro Design Duo, with double symmetrical coating on the front and back, available in weights between 250 and 500 g/m²

About Industrialbox

Industrialbox has a history spanning more than 70 years, throughout which tradition has been skilfully intertwined with the most innovative production technologies. The company creates robust boxes, cases and containers for leading national and international brands in the worlds of fashion, perfumery, cosmetics, pharmaceuticals, confectionery, jewellery, wine and spirits.

The designs are tailor-made and demonstrate great attention to every tiny detail. The added value is an in-house team that designs customised solutions using the most advanced technology. Particular attention is paid to creating packaging interiors that allow products to be shipped around the world securely.

Industrialbox internally integrates all the departments needed for the most diverse paper and card processes, as well as industrial packaging processes: design and prototyping, pre-press and colour proofing, offset and hot stamping, cold foil, embossing, lamination, die-cutting, assembly, filling and storage. Through the integration of techniques, production processes and high-quality materials, they offer an all-round service and value-added products that are difficult to find anywhere else on the market.