Be part of the journey: from renewable resources to recyclable, paper-based packaging

Sappi’s new video provides insight on the lifecycle of its fibre-based, recyclable packaging solutions

As a leading manufacturer of flexible packaging papers with integrated barriers and heat-sealability properties, Sappi is at the forefront of forward-looking packaging materials. Our latest video takes you on a journey through the entire lifecycle of our fibre-based packaging products, showcasing how we unlock the power of trees to create packaging solutions that are both environmental-friendly and functional.

It all begins with renewable resources

One of the fundamental pillars of sustainable packaging is the use of renewable resources. For Sappi, it is essential that the trees for the woodfibre are sourced from sustainably managed forests with FSC or PEFC certifications. These forests are carefully managed to ensure the trees’ long-term vitality. We convert woodfibre into pulp by means of a meticulous process, laying the foundation to produce high-quality packaging materials.

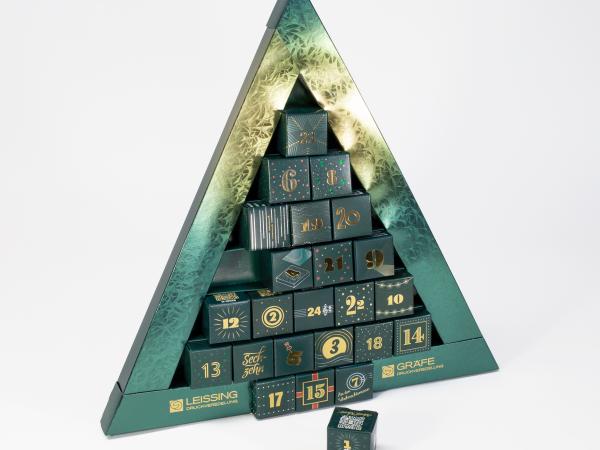

Packaging paper with different printing surfaces

Our journey continues as we transform pulp into paper. To address the needs of our customers, Sappi offers a wide range of different printing surfaces, including matt, silk and gloss. These allow the packaging to support the brand image of the product and to ensure a lasting impression: for instance, with a matt finish for a more natural appearance of organic food, or a glossy surface for high-end products and stronger shelf-impact at POS.

New barrier coater: boundless possibilities for renewable packaging alternatives

Sappi not only attaches great importance to appearance, but also to the paper’s functionality – with product protection being a top priority. Drawing on its far-reaching expertise in paper-coating technology, Sappi produces a wide range of functional paper packaging for both food and non-food applications. Sappi recently put an all-new type of barrier coating machine into operation at the company’s Alfeld site in Germany. Depending on specific requirements and applications, a variety of coating technologies can be used on the new machine. It can integrate barriers against oxygen, water vapour, grease, mineral oil (MOSH/MOAH), and add heat-sealability into our packaging papers. An integrated coating kitchen, offering new possibilities for the in-house development of coating recipes, will also be available in the future.

Sappi uses a multilayer coating and water-based dispersion technology to produce environmentally friendly packaging solutions

The machine and state-of-the-art technology will help bring to market further alternatives to non-recyclable packaging based on fossil raw materials.

Read more about Sappi’s new barrier coating machine: https://www.sappi-psp.com/insights/inspiration/a-milestone-in-the-development-and-production-of-a-new-generation-of-high

Our journey doesn’t end there. Once the coatings are applied, our packaging papers are meticulously finished to the required formats. The final reels of our packaging papers are packed using a fully automated process that prioritizes efficiency and precision. This ensures that our products reach our customers in the best possible condition, ready to serve their varied packaging needs.

And finally, back to the paper waste stream

Ultimately, this only represents the beginning. Once it has served its purpose, our fibre-based packaging material becomes part of the paper waste stream, ready to be recycled – completing the cycle of sustainability.

At Sappi, we are dedicated to sustainable packaging: from renewable resources to recyclable materials. Join us on this journey as we continue to innovate. Always striving to make packaging that is not only functional and reliable but also environmentally responsible. All with the aim of building a more sustainable future.