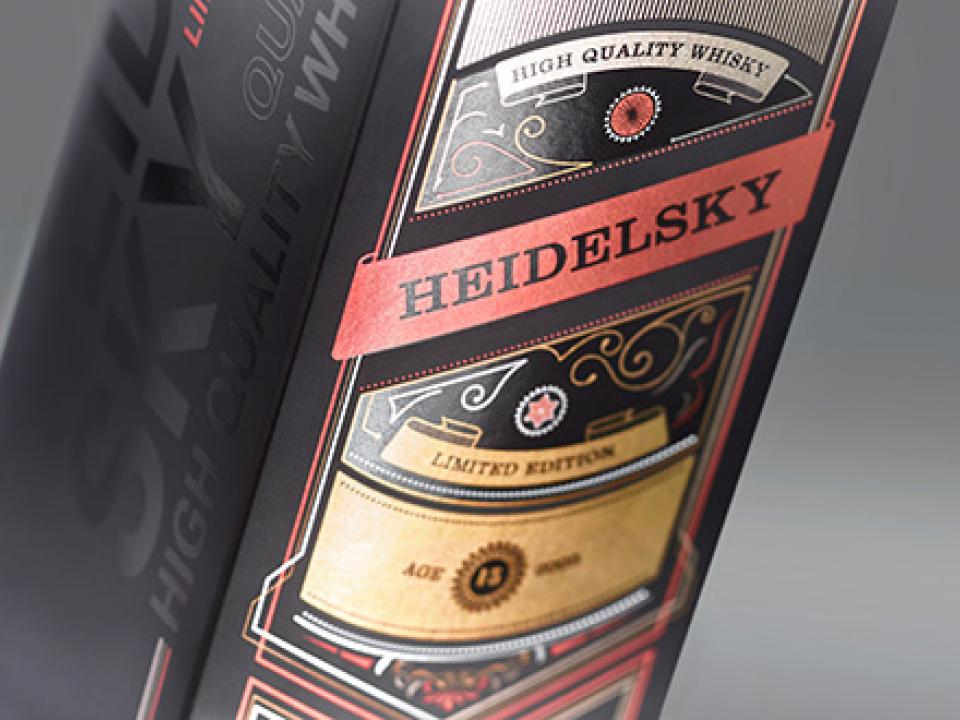

CHINA PRINT 2021: Heidelberger Druckmaschinen AG and Sappi make an impression with Heidelsky print job

When the leading provider of sheet-fed offset printers and an innovative provider of speciality papers and boards collaborate on the live demonstration of an exhibition print job, high-quality, impressive results can be expected.

Although trade fairs are still restricted in many parts of the world, CHINA PRINT 2021 took place as usual in Beijing. In addition to presenting the current generation of printers and new software solutions, Heidelberger Druckmaschinen AG (Heidelberg) celebrated a world premiere by showcasing the latest Speedmaster model to the audience – the Speedmaster CX 104. Also included was Sappi’s ultra-bright solid bleached board Algro Design Nature, which served as the perfect substrate for the ‘Heidelsky’ print job that was prevented live.

‘These are the type of objects for which Sappi’s range of solid bleached boards from the Algro Design portfolio were developed based on maximum consistency and productivity with the highest-quality print and finishing results.A live demo like this is a fantastic opportunity for discerning customers in the growing Chinese market to experience first-hand the possibilities with Sappi and our global capabilities using the latest technology from our long-term partner Heidelberg.’

Heidelberg shows the potential of cold transfer

Heidelberg’s launch of the Speedmaster CX 104-9+L at CHINA PRINT underscores its leading role in the packaging industry as well as its expertise in single-pass inline finishing.

The enthusiastic visitors to the booth were shown how premium, practical, high-grade product packaging is created for a fictitious whiskey brand. ‘Heidelsky’ showcased the versatility of outstanding and economical inline finishing using cold transfer technology in combination with matt/gloss coating effects in the form of spot/spot conversion with the Speedmaster CX 104-9+L.

Technical details at a glance:

- Printed in UV

- Print sequence adhesive cold foil (silver foil)

- 2x Pantone Blue (eventually also 2x black)

- Black-magenta-yellow

- Matt varnish spot in printing unit

- Gloss varnish spot in coating unit (via flexo plate)

- Printed on Sappi Algro Design Nature 300 g/m²

Heidelsky highlights technological strengths

To demonstrate the strengths of cold transfer technology, extremely fine, ornamental elements were used on the one hand, contrasting with somewhat more basic elements on the other.

Another major benefit is that the cold transfer can be overprinted after application of the foil. This enables a wide range of metallic tones to be achieved, based on a transfer, in this case a silver foil. A benefit that was also utilised in ‘Heidelsky’. Visitors to the booth enjoyed a highly visible and tactile effect in combination with the matt/gloss effect, emphasising the elegant look.

What sets the new Speedmaster CX 104 from Heidelberger Druckmaschinen AG apart

The new 104 sheet-size printer offers customers in commercial, packaging and label printing access to cutting-edge sheet-fed offset technology from Heidelberg with exceptional cost-efficiency. When choosing model variants, customers benefit from the free scalability of the system up to push-to-stop functionality as well as custom configurations with up to 15 printing or coating units at present. The new coating unit can also be converted much faster and more conveniently, thus increasing application flexibility.

Sappi’s Algro Design Nature solid bleached board for ‘Heidelsky’

With its high brightness and surface quality, Sappi’s Algro Design solid bleached board range has been setting the standard in colour reproduction for complex graphic and high-end packaging applications for many years. Consequently, based on a wide range of pre-tests, Algro Design Nature was well suited for the Heidelsky print job.

‘In particular with regard to the surface quality and special requirements for smoothness, brightness and texture for optimal cold transfer quality, it was clear how ideal Algro Design is for cold transfer applications. In addition, and with a view to the subsequent finishing processes, other key factors such as good sheet stability as well as the creasing and die-cutting properties of the substrate are very important to us,’ explains Matthias Trauth, print application specialist at Heidelberg.

Two strong partners, one mutual success

A premium product, a smooth printing process and two satisfied partners – the live Heidelsky print job was a resounding success, evident not only from the response of the visitors to the fair, but also from the numerous samples that were eagerly taken. With this in mind, Heidelberg and Sappi look forward to presenting our customers with further exciting innovations in the future.