High-quality finishing: cold transfer from KURZ on Algro Design Nature

The high graphic quality and cold transfer technology of KURZ in an optimised process point the way to optimum finish results.

As a finisher and manufacturer of embossing solutions for surface decoration, KURZ knows that Algro Design Nature is the perfect basis for premium packaging and complex graphic applications. As Sappi and KURZ have been working together closely for a long time on many levels, Kurz had no doubts about turning to Algro Design again for its new sample series.

Algro Design Nature as the perfect basis

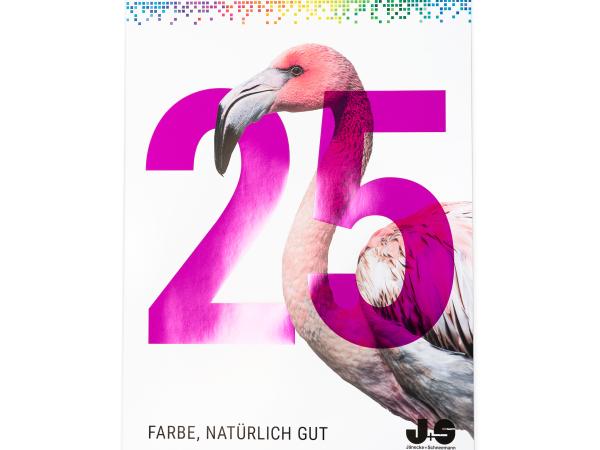

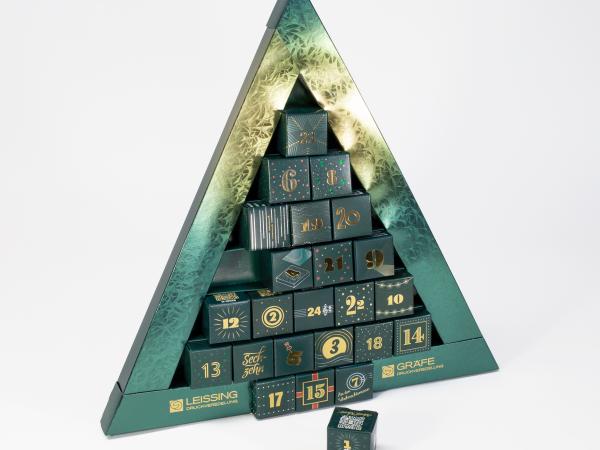

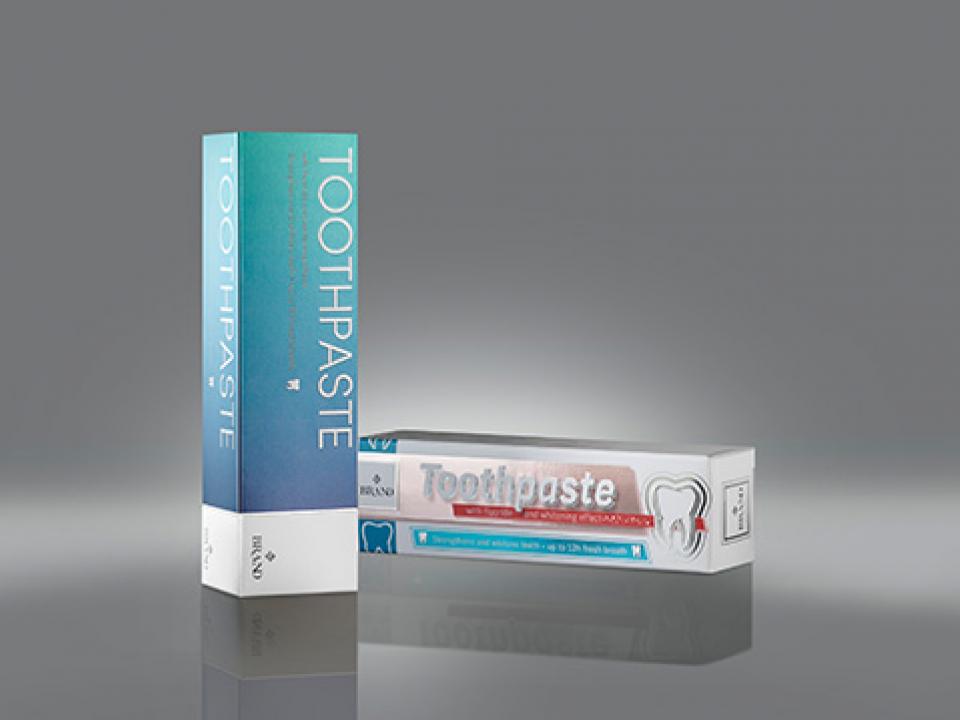

The finisher and manufacturer of embossing solutions has produced a sample series on the solid bleached board coated on one side, which impressively demonstrates the finish results that are possible using cold transfer technology. The samples were created in an offset printing process in partially printed metallised form on Sappi Algro Design Nature. With great success: the solid bleached board accentuates the requirements and brand messages that are closely connected to a natural look and feel.

With its new series, KURZ also wants to show that cold transfer technology has advantages over the metallised laminated board that is commonly used in the market. The technology is particularly impressive in terms of recycling. The complete deinking ability is another sustainability plus. In addition, since no white has to be printed due to the high basic brightness of Algro Design Nature, this enables higher contrasts, while the high gloss level can also make a strong impression.

Outstanding look and feel

The samples were printed and metallised in an inline procedure. The matt varnish was then applied in a second print process. For cost efficiency, using a seven-colour printing machine with a cold foil unit, both the primer and the subsequent coating could be applied inline in a single pass. To ensure a higher-quality look and feel, the samples were then blind-embossed.

To demonstrate that the cold transfer technology from KURZ offers, at the very least, equivalent, if not better, finish results, comparison samples were also printed on already metallised-laminated board using the same design. The results confirm the claim. However, it is above all the benefits in terms of sustainability that make cold transfer technology from KURZ the clearly superior method for achieving high-quality finish results.

‘We are pleased to be able to support KURZ with our substrates,’ says Lars Scheidweiler, Head of Packaging Solutions at Sappi. ‘We go back so many years, and I continue to be impressed by KURZ time and time again. The aspiration and self-image and the uncompromising desire to strive for nothing short of 100% is simply part of the DNA of KURZ and this is tangible throughout the company. To be honest, I know that we are unlikely to find a better benchmark to meet the constantly growing demands for perfection and quality consistency in the packaging market on the part of our customers.’

KURZ closes the gap in the material cycle

With KURZ RECOSYS®, the carrier film can now also be recycled, because, after the application process, the carrier material can be completely returned to the material cycle. It is used to produce recycled material for the plastics industry. With this, LEONHARD KURZ is the only company in the world to currently offer a PET return system like this.

This enables high quality, innovation and efficiency to be combined optimally in the samples.