Beyond single metrics: Why comprehensive sustainability considerations matters in packaging innovation

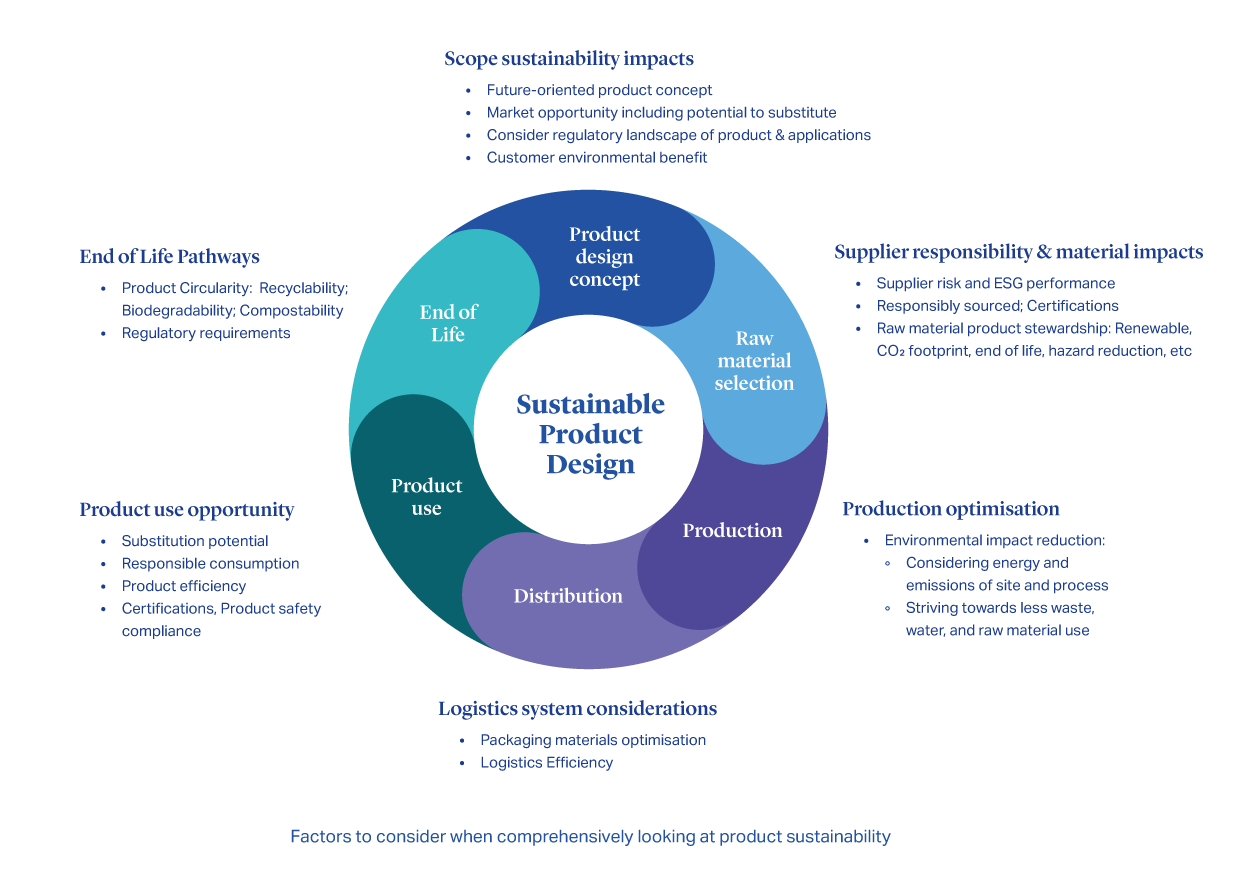

At Sappi Europe, we embrace a comprehensive sustainability approach that encompasses the complete product lifecycle, from raw material sourcing and production efficiency through to distribution, end-use, and recyclability.

This holistic view recognises that meaningful sustainability in flexible packaging requires balancing multiple environmental factors including carbon emissions, resource efficiency, water and energy consumption, and circularity principles.

This broader perspective reflects evolving market demands and regulatory requirements. Through extensive customer collaboration, we've observed that whilst packaging recyclability remains a critical focus, optimising for any single sustainability metric can sometimes lead to suboptimal environmental outcomes across other important factors. Therefore striving for the right balance should be the main goal.

Understanding customer sustainability challenges

Through extensive customer collaboration, we've encountered situations where improving recyclability performance can actually increase overall environmental impact. The most common example involves increasing paper weight to improve recyclability score. This comprehensive sustainability perspective has revealed an important paradox in the packaging industry.

"We frequently work with customers who ask how to improve their packaging's recyclability. Though we can certainly do that, we also explore whether it's the right approach for their specific sustainability goals. Increasing paper weight with the sole purpose of improving a recyclability increases the use of resources and leads to higher emissions, ultimately making the solution less sustainable, even when the functional performance is identical."

A practical example illustrates this challenge: increasing paper weight from 50gsm to 100gsm to improve recyclability from a theoretical 90% to 95% yield—a mere 6% improvement—more than doubles resource consumption including CO₂ emissions, energy, water, and land usage. The result is a product with a marginally enhanced recyclability score that is significantly less sustainable overall.

"We're working with customers to understand how optimising for one factor can sometimes impact others," explains Gustavo. "This is where our comprehensive approach to evaluating carbon footprint, resource consumption, production efficiency, and circularity becomes essential." Optimising product sustainability requires navigating tradeoffs and finding the optimum balance, together with our customers.

Advanced sustainability assessment and innovation

When developing our innovative packaging products, we consider sustainability from a comprehensive perspective to assess multiple interconnected dimensions.

This systematic approach examines the complete product lifecycle—from end-of-life pathways and recyclability requirements through raw material selection and supplier responsibility, to production optimisation and distribution logistics. Rather than focusing on any single metric, this helps ensure that changes in one area don't inadvertently compromise performance in another, enabling more sustainable packaging solutions that balance environmental impact with functional requirements.

This holistic approach enables us to work with customers on better optimised solutions rather than simply ticking boxes on generic sustainability checklists.

"Our customers increasingly want to understand the full sustainability profile of their packaging decisions. They're asking smarter questions about trade-offs and looking for partners who can help them navigate complexity rather than just provide simple answers."

Sappi’s functional papers demonstrate how advanced material science can address multiple sustainability criteria simultaneously. These solutions use ultra-thin, water-based varnishes—8 to 10 times thinner than human hair—applied through sophisticated dispersion technology to create true monomaterial solutions, capable of replacing heavier multilayer structures or fossil-derived materials.

The paper substrate isn't just a carrier; it's the fundamental structural component that enables the barrier system to function and ultimately offers a much more sustainable and renewable solution. This integrated approach has enabled some applications to achieve CO₂ emissions reductions as high as 75% or more compared to conventional plastic and multilayer composites, whilst maintaining recyclability in paper waste streams.

Collaborative solutions and future strategy

Our Guard product portfolio also exemplifies this systems-thinking approach. Products like the high barrier paper Guard Pro OHS for confectionery applications, and barrier papers Guard Twist Gloss for candy wrappers and Guard Duo for ice cream cone packaging, aren't just recyclable alternatives, they represent solutions designed to balance recyclability with functional performance, production compatibility, and sustainability. These solutions run on existing production equipment, helping customers transition to more sustainable packaging without major capital expenditure. This compatibility factor often proves decisive in real-world implementation.

As we continue developing our sustainable packaging portfolio through collaboration across the entire value chain—working with raw material suppliers, packaging machinery manufacturers, converters, and recyclers—our focus remains on fit-for-purpose design that balances multiple sustainability factors rather than maximising any single metric.

For brand owners seeking to navigate the complexity of sustainable packaging decisions, we offer both innovative materials and the collaborative expertise to help them with the transition to paper-based solutions. The goal isn't just better packaging; it's packaging that genuinely serves both product protection and environmental stewardship.